OEM/ODM Manufacturer Capsule Inspection Detecting Sorter Sorting Machine

Short Description:

Our organization has been specializing in brand strategy. Customers’ satisfaction is our greatest advertising. We also provide OEM company for OEM/ODM Manufacturer Capsule Inspection Detecting Sorter Sorting Machine, Together with our endeavours, our products and solutions have won the trust of customers and been very salable both here and overseas. Our organization has been specializing in brand strategy. Customers’ satisfaction is our greatest advertising. We also provide OEM co...

Our organization has been specializing in brand strategy. Customers’ satisfaction is our greatest advertising. We also provide OEM company for OEM/ODM Manufacturer Capsule Inspection Detecting Sorter Sorting Machine, Together with our endeavours, our products and solutions have won the trust of customers and been very salable both here and overseas.

Our organization has been specializing in brand strategy. Customers’ satisfaction is our greatest advertising. We also provide OEM company for Capsule Sorting Machine, Detecting Machine, Sorting Machine, In order to meet more market demands and long-term development, a 150, 000-square-meter new factory is under construction, which will be put into use in 2014. Then, we shall own a large capacity of producing. Of course, we will continue improving the service system to meet the requirements of customers, bringing health, happiness and beauty to everyone.

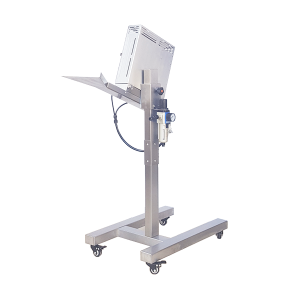

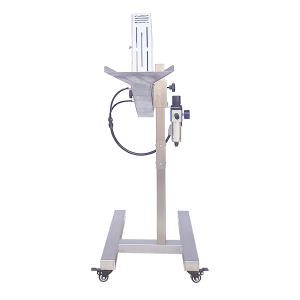

Empty Capsule Sorter(ECS)

–precisely sort out empty & half-filled capsules

Introduce:

Empty Capsule Sorter(ECS) uses bernoulli principle to create stable and adjustable suction out of compressed air,sorting capsules by weight.Heavy ones will pass through the port while light ones,especially those unfilled capsule shells will be sucked into other tunnels.

Purpose

After being connected,it will sort capsules fast from the filler.Empty capsules and half-filled capsules caused by shell quality (samll capsule,single half,prelocking),the filler(powder toss,vacuum degree) or material characteristics(pellet adhesion,electrostatic interaction).It is an effective way to prevent bad capsules from the market,avoiding negative feedbacks.

Advantages:

1. Highly efficient, with a max output of 7000 capsules/min, which can be connected to any kind of capsule filling machine.

2. Effective results. ECS uses secondary separation methods with almost 100% sorting rate.

3. Convenient, small size with proper design, powered by compressed air, easy cleaning and maintenance.

4. No change parts for different size of capsules, applicable for any sorting process.

5. Very valuable for sorting out empty and light capsules to prevent them from the market and avoid complains effectively.

Parameter

| Model | Applicable for | Speed | Power | Air Supply | Dimensions |

| ECS | All Hard Capsules | 7000pcs/min | N/A | 5~8 bar | 700*300*530mm |